One hope buoying nuclear energy advocates has been the promise of “small modular reactor” designs. By dividing a nuclear facility into an array of smaller reactors, they can largely be manufactured in a factory and then dropped into place, saving us from having to build a complex, possibly one-of-a-kind behemoth on site. That could be a big deal for nuclear’s persistent financial problems, while also enabling some design features that further improve safety.

On Friday, the first small modular reactor received a design certification from the US Nuclear Regulatory Commission, meaning that it meets safety requirements and could be chosen by future projects seeking licensing and approval.

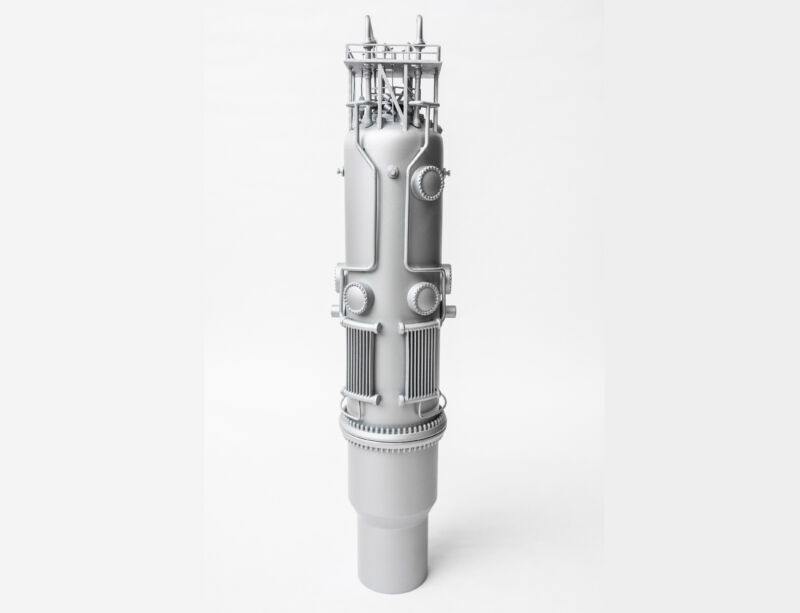

The design comes from NuScale, a company birthed from research at Oregon State University that has received some substantial Department of Energy funding. It’s a 76-foot-tall, 15-foot-wide steel cylinder (23 meters by 5 meters) capable of producing 50 megawatts of electricity. (The company also has a 60-megawatt iteration teed up.) They envision a plant employing up to 12 of these reactors in a large pool like those used in current nuclear plants.

The basic design is conventional, using uranium fuel rods to heat water in an internal, pressurized loop. That water hands off its high temperature to an external steam loop through a heat exchange coil. Inside the plant, the resulting steam would run to a generating turbine, cool off, and circulate back to the reactors.

The design also uses a passive cooling system, so no pumps or moving parts are required to keep the reactor operating safely. The pressurized internal loop is arranged so that it allows hot water to rise through the heat exchange coils and sink back down toward the fuel rods after it cools.

In the case of a problem, the reactor is similarly designed to manage its heat automatically. The control rods—which can encase the fuel rods, blocking neutrons and halting the fission chain reaction—are actively held in place above the fuel rods by a motor. In the event of a power outage or kill switch, it will drop down on the fuel rods due to gravity. Valves inside also allow the pressurized water loop to vent into the vacuum within the reactor's thermos-like double-wall design, dumping heat through the steel exterior, which is submerged in the cooling pool. One advantage of the small modular design is that each unit holds a smaller amount of radioactive fuel, and so it has a smaller amount of heat to get rid of in a situation like this.

NuScale submitted its design at the end of 2016, and approval of a new type of reactor was no small task. The company says it submitted over two million pages of requested information throughout the process. But at the end, the agency signed off: “The NRC concludes the design’s passive features will ensure the nuclear power plant would shut down safely and remain safe under emergency conditions, if necessary.”

A couple of additional modular light water reactors are about to start the certification process. Separately, a handful of companies have plans to submit very different designs, like molten salt reactors. But these are even farther out.

NuScale, on the other hand, says it aims to have its first reactors deployed “by the mid-2020s.”

reader comments

638